莱芜钢铁集团粉末冶金有限公司始建于1987年,经过三十年的建设、改革和发展,公司现已具备年产20万吨钢铁粉末生产能力,且同时拥有还原制粉、水雾化制粉、水气联合雾化制粉、惰性气体非真空雾化制粉生产线的现代化大型钢铁粉末生产企业。公司是国家高技术研究发展计划(863计划)成果产业化基地,国家新材料产业化基地骨干企业,国家火炬计划重点高新技术企业,中国专利山东明星企业,山东省钢铁粉末创新战略联盟理事长单位,中国粉末冶金创新战略联盟副理事长单位,中国钢结构协会粉末冶金分会理事长单位。 公司主要产品为还原系列、水雾化系列钢铁粉末和高性能合金特种粉末材料,产品荣获“山东名牌”称号。公司已通过ISO9001质量体系认证,产品广泛应用于汽车、摩托车、家电、化工等十几个行业,畅销国内25个省、市、区,并出口日本、韩国等国家,国内市场占有率达27%。 新时代、新征程、新跨越,莱芜钢铁集团粉末冶金有限公司将以新的形象和更强的综合竞争实力向您提供更高档次和更优质的产品及商业服务,公司将向着“打造具有国际竞争力的钢铁粉末供应商”强力迈进! Laiwu Iron and Steel Group Powder Metallurgy Co., Ltd. was founded in 1987, after 30 years of development, the company has reached annual production capacity of 200,000 MT. The company has become a modern large-scale steel powder production company with reduced powder line, water atomized powder line, water & vapor combined atomized powder line and inert gas non-vacuum atomized powder line. The company is the base of the national high-tech research and development program (863 Program) industrialization achievement; the backbone enterprise for new material industrialization base; one of the key high-tech enterprises of the state Torch Plan; the Shandong’s star enterprise of China patent; member of Shandong Iron and Steel Powder Innovation Strategic Alliance Association, member of China Powder Metallurgy Innovation Strategic Alliance Association, member of China Steel Structure Association Powder Metallurgy Branch. The main kinds of products include reduced powder, atomized powder and high-performance alloy special powder. Products are rewarded as the "Shandong famous brand". All products are confirmed to ISO9001 quality system. Products are widely used in automobile, motorcycle, household applicants, welding, chemical industry, etc. Domestic market share has reached up to 27%. Products are sold well in 25 provinces and cities of China and exported to Japan, Korea, Vietnam, Thailand, and other countries. The new era, Laiwu Iron and Steel Group Powder Metallurgy Co., Ltd. will provide customers with a higher quality level products and business services. The company will continue to move forward with the goal of "building an internationally competitive powder supplier".

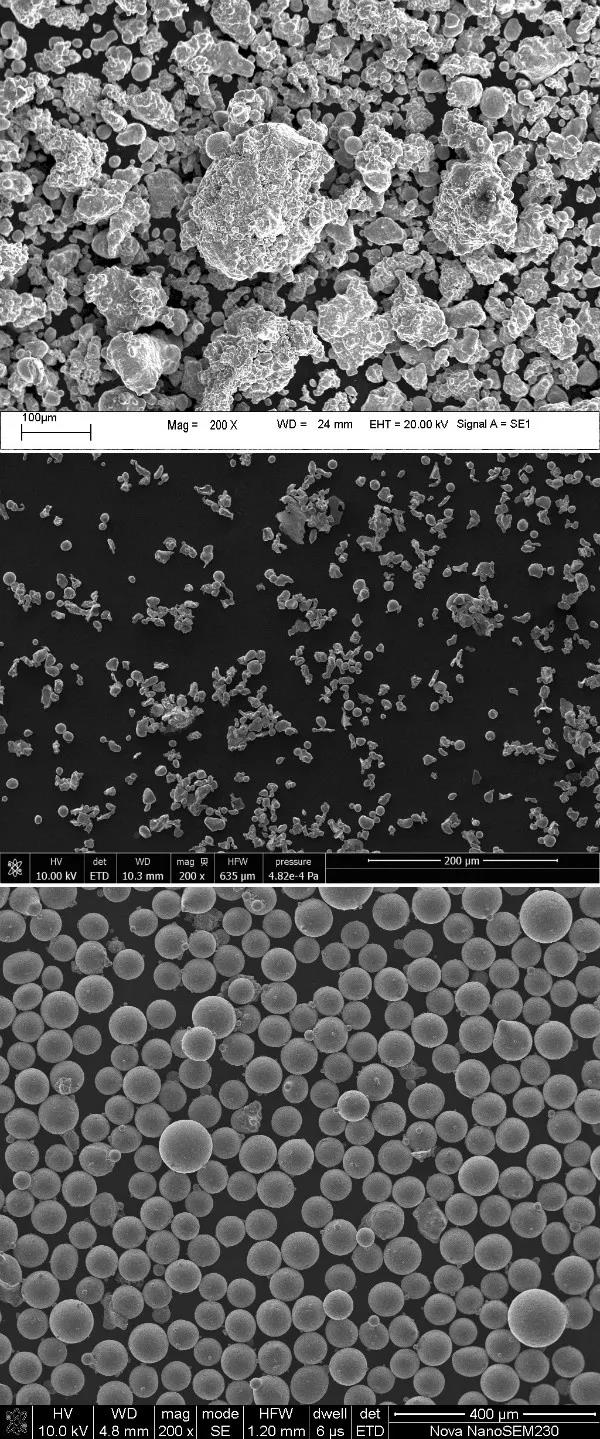

特种合金粉末 Special alloy powder

主要生产的特种合金粉末有压制不锈钢粉、MIM用不锈钢粉、预合金胎体粉、金刚石触媒粉、磁粉芯及电感用软磁粉及其他合金粉。 The main production of special alloy powders include pressed stainless steel powder, stainless steel powder for MIM, pre-alloyed carcass powder, diamond catalyst powder, magnetic powder core and soft magnetic powder for inductors and other alloy powders.

还原铁粉 Sponge Iron Powder

还原铁粉以钢铁厂轧钢剥落的废弃物氧化铁鳞为主要原料,焦末为还原剂,石灰或石屑为脱硫剂,按一定比例搭配,氧化铁磷经过烘干、筛分、磁选、球磨、筛分、磁选一系列工序后制得装罐铁鳞,然后装罐装车在隧道窑中,使用炼钢、炼铁和焦化过程中产生的混合煤气加热,在1150℃的条件下进行一次还原得到海绵铁,再经过清刷、粗破、细破、磁选、筛分制得80目以下的一次粉,在钢带式还原炉纯氢气氛下进行二次还原,完成脱碳、脱氧和加工硬化的消除,二次还原后的粉饼经破碎、筛分、合批、包装得到最终不同品种的还原铁粉。 The sponge iron powder is mainly made of iron scale, coke powder and the lime, the mixture of the raw material after drying, sieving, magnetic separation, ball milling, sieving and magnetic separation. Then is heated in the tunnel kiln by gas at 1150 °C, then get the sponge iron bloks, then breaking, magnetic separation and screening get the 80 mesh first reduced powder. Then the first reduced powder is reduced in the reduction furnace for decarbonization, dexidation and elimination of hardening. The powder cake after breaking,sieving, then finally get the reduced iron powder.

水雾化钢铁粉末 Water Automized Powder

雾化铁粉采用优质废钢为主要原料,在电弧炉中进行冶炼,在冶炼过程中加入不同的合金,在精炼炉中得到成分合格的钢水,经过高压水雾化、湿式磁选、脱水、烘干、冷却、筛分得到雾化生粉,在钢带式还原炉纯氢气氛下进行精还原,还原后的粉饼经破碎、筛分、合批、包装得到水雾化纯铁粉或水雾化合金钢粉。 The atomized iron powder is made of scrap steel, and different alloys are added in the smelting process then get refined in the refining furnace. Then the steel liquid after high-pressure water atomization, wet magnetic separation, dehydration, drying, cooling, screening then get the atomized raw powder. Then the first reduced powder is reduced in the reduction furnace for decarbonization, dexidation and elimination of hardening. The powder cake after breaking, sieving, then finally get the water automized powder.

无偏析混合粉 Premixed Powder

无偏析预混合粉是为了提高铁基产品的力学性能,在铁粉中加入的C、Ni、Cu、Mo等合金元素,从而改善粉末流动性能、提高制品尺寸精度及力学性能,其主要方法有:粘结混合法与直接混合法。粘结混合法制备原理是以铁粉为基粉与合金元素粉末预混合后,喷入粘结液进行粘结,同时继续混合并烘干使溶剂挥发,之后再加入润滑剂混合均匀并筛分合批得到成品。直接混合法直接将基粉与辅料、润滑剂进行混合并筛分包装得到成品。在生产实际中这两种混合方式都得到广泛应用。 The non-segregated premix powder is to improve the mechanical properties of products. The auxiliary such as C, Ni, Cu and Mo are added to the powder to improve the flow properties of the powder, and to improve the dimensional accuracy and mechanical properties of the products, the main methods are Bonding Mixing Method and Direct Mixing Method. The principle of the bonding method is to spray the bonding liquid onto the mixture of powder and auxiliary materials. The direct mixing method directly mixes the base powder with the auxiliary materials. Both mixing methods are widely used in production practice.

|